When a powdered drink dissolves instantly — no clumps, no grit, just smooth flavor and clean texture — that’s agglomeration at work.

Agglomeration is a critical step for brands that want every serving to mix perfectly and taste consistent from first sip to last. It’s the process that elevates texture, solubility and taste — creating a more enjoyable product from the first pour to the last sip.

At Corim Industries, every part of the process — from formulation to agglomeration and packaging — happens on-site. That level of control means faster development, shorter lead times, tighter quality oversight and products that meet exact specifications. By managing the entire process in one place, we give partners the confidence that every blend will perform as smoothly in production as it does in the cup.

What Exactly Is Agglomeration?

At its core, agglomeration is the controlled transformation of fine powders into larger, porous and more uniform granules. This physical restructuring improves nearly every handling and sensory property of the material.

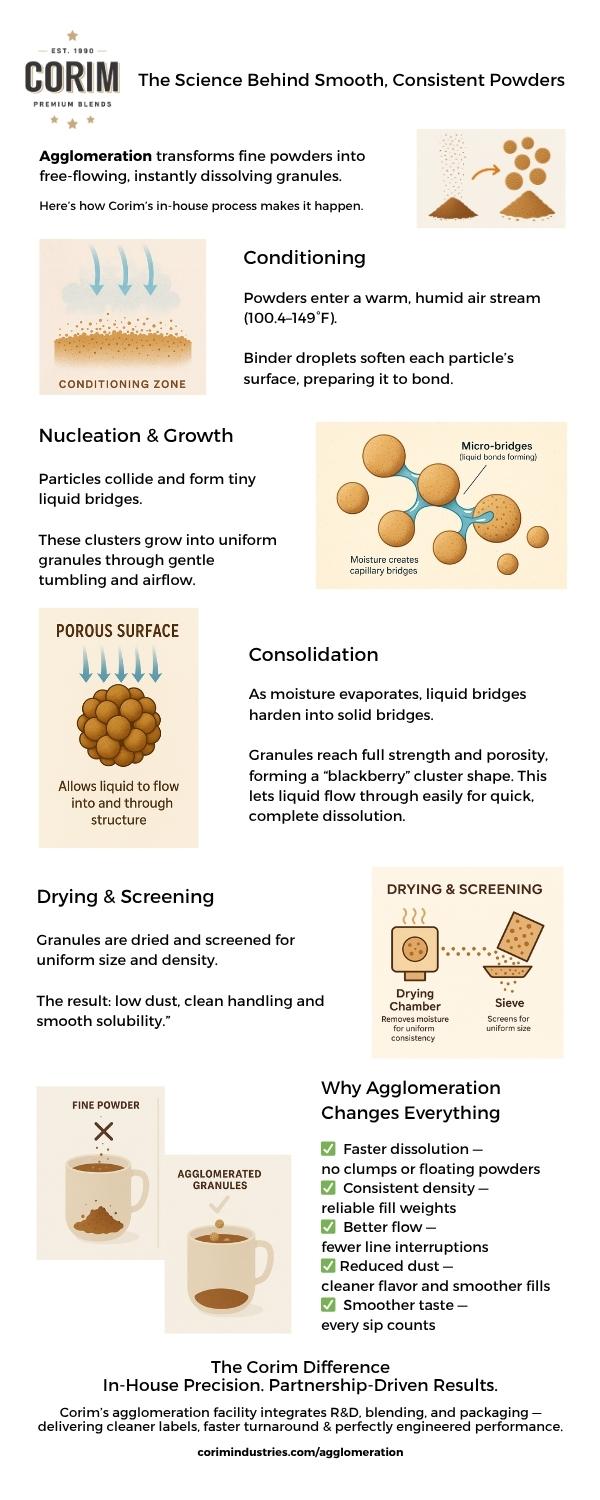

Here’s what happens inside the system:

Here’s what happens inside the system:

- Spraying — Binder Droplets / Powder: A fine mist is sprayed onto the powder surface to introduce moisture and begin particle adhesion. Controlled heat (typically between 38-65°C / 100.4–149°F) and air flow prepare each particle to bond.

- Nucleation & Growth — Liquid Bridge: As particles collide, tiny liquid bridges form between them, encouraging small clusters to join together. The residence time and humidity profile determine the granule’s growth and density.

- Consolidation / Solidifying — Solid Bridge: As moisture evaporates, the temporary liquid bridges harden into stable solid bonds. The porous structure that remains allows liquids like water or milk to penetrate quickly when reconstituted.

- Agglomeration — “Blackberry Structure”: The final granule forms — a strong, open structure resembling a blackberry cluster. This shape improves solubility, flowability and texture across a wide range of powdered beverage systems.

Unlike spray drying or extrusion, Corim’s agglomeration process uses no chemical binders or additives. It’s purely mechanical and thermal, producing clean-label powders with exceptional performance and consistency.

Binding Dust and Beyond: Agglomeration in Other Industries

While Corim applies agglomeration to improve solubility, texture and product performance in powdered beverages, the same principles are widely used outside the food and nutrition space. In baking, for example, flour and water naturally agglomerate to form cohesive dough. In mineral and chemical processing, agitation agglomeration is often used to bind dust and create larger, more stable granules for safer handling and transport.

This technique uses motion and a liquid binder to form pellets or granules that improve flowability, reduce airborne dust and enhance overall material performance—the same science that helps drink mixes dissolve smoothly also supports cleaner, safer and more efficient processing in other industries.

Visualizing the Agglomeration Process

Agglomeration combines heat, motion and moisture to transform fine powders into uniform, instantly dissolving granules. This infographic demonstrates how each stage works together to create smooth, consistent performance in every formulation.

Why It Matters for Formulation and Production

Fine powders behave unpredictably. Their small particle size creates high surface area, leading to poor flow, dusting and non-uniform filling. Agglomeration mitigates these issues in measurable ways:

Improved Flow Properties: Granules flow freely through hoppers and augers, reducing bridging and segregation during packaging

Improved Flow Properties: Granules flow freely through hoppers and augers, reducing bridging and segregation during packaging- Controlled Bulk Density: Customizable from light (instant drink mixes) to compact (nutritional blends), enabling consistent fill weights and stable shelf life

- Rapid Wetting and Dispersion: Porous granule surfaces allow liquids to infiltrate quickly, preventing floating or clumping

- Reduced Dust & Segregation: Agglomeration stabilizes each particle, reducing dust during blending, filling and transport. Lower dust levels mean cleaner flavor expression, more precise fills and consistent quality from batch to batch.

- Enhanced Mouthfeel: The uniform particle structure leads to smoother textures and more even flavor release

Cleaner, more stable granules mean stronger flavor retention, smoother flow through packaging lines and a final product that meets brand expectations for consistency and shelf appeal. These technical gains directly support both manufacturing efficiency and consumer perception — two sides of the same success story.

Applications in Beverage Development

Agglomeration plays a defining role in the development of instant and functional beverage products. Whether the goal is better solubility in cold liquids, smoother texture in protein blends or faster dispersion in hot beverages, agglomeration allows precise control over performance and mouthfeel.

For brand partners, that means the ability to launch products that meet modern consumer expectations — convenience, clean taste and consistent results in every preparation. From private label instant coffee and tea to fortified cocoa, creamer and nutrition powders, agglomeration ensures that every blend behaves exactly as intended.

Because Corim manages every step in the process—R&D, formulation, blending, agglomeration and packaging— at a single facility, brands can move from lab concept to shelf-ready product faster and with fewer quality hurdles.

Cleaner Powders, Consistent Quality

Corim’s agglomeration process creates stable, low-dust granules that mix evenly, fill precisely, dissolve smoothly and perform reliably — delivering the clean flavor and consistency consumers expect in every cup.

Clean Label & Sustainability Advantages

Agglomeration supports the growing demand for clean label, sustainable products. Corim’s process relies purely on heat, water and air — no chemical binders or artificial agents. The result is a clean, straightforward formulation that meets growing consumer demand for transparency.

The process also enhances sustainability through operational efficiency. Better flowability and uniformity reduce waste during filling. Lower dust also improves flavor stability and packaging presentation — helping brands deliver a cleaner, higher-quality product to consumers. Improved solubility minimizes product residue during preparation. These small efficiencies add up — lowering resource use across the product’s lifecycle and helping partners advance their sustainability commitments without sacrificing performance.

The Corim Difference

Corim’s in-house agglomeration line is fully integrated with our blending and packaging operations, giving us total control over every variable — from humidity and air velocity to granule size distribution and product density.

Because we manage this capability internally, we can adjust formulations in real time, fine-tune performance and move seamlessly from pilot to full-scale production. Our R&D team works closely with partners to:

- Optimize solubility and dispersibility for specific beverage systems

- Improve flow characteristics for high-speed stick pack or pouch lines

- Customize density and moisture targets for a variety of shipping environments

The result: low-dust powders that not only dissolve better but perform flawlessly from blending to filling to the consumer’s cup.

Turning Precision into Consumer Experience

Agglomeration is one of the most critical steps in creating a product consumers truly enjoy. By controlling how powders bind, flow and dissolve, Corim ensures every mix performs flawlessly in production and delivers the smooth texture, balanced flavor and consistent quality that define a great beverage experience.

We’ve helped brands develop an extensive range of functional products. The examples below are just a glimpse of what we already do:

We’ve helped brands develop an extensive range of functional products. The examples below are just a glimpse of what we already do: